In a moment in which innovation and collaboration are essential for driving significant advancements, we would like to introduce one of our Elewit Partners: Anisopter. Founded in 2021, it emerged in response to truss-related structural challenges, inspired by an R+D European project called ANISOPTER. Its revolutionary work focuses on overcoming traditional structural limitations, offering an ingenious connection system that uses light and hollow nodes, designed to join on-site ducts without soldering. This innovative solution not only promises construction efficiency, but also aims to transform key sectors, from electricity transmission to renewable energy generation.

We spoke with José Ramón López Blanco, scientist and founder of Anisopter, to explore the impact of the technology and the experience of collaborating with Elewit in the search for solutions to aid in the energy transition and sustainable construction.

1. Can you tell us how Anisopter was founded?

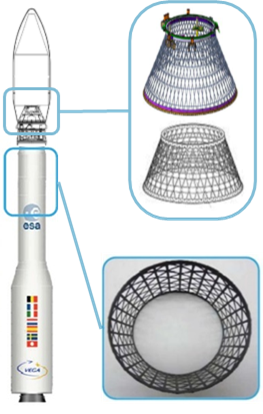

We took our name from a European R+D project called ANISOPTER (ANISogrid OPTimization servER) which we delivered in 2019 together with a software company. After investigating in this project, the optimisation of Anisogrid lattice structures, a type of truss used in the aerospace sector, we realised they had huge potential in terrestrial markets if they could be made with ducts.

We also asked ourselves why they were not routinely used in applications that required truss towers on a large scale, such as the electricity transmission or telecommunication sectors, to give some examples with an increased social and environmental impact. It seems that the issue in finding these types of highly efficient structures is due to the fact that there is no cost-effective technology to build complex geometric designs at a reasonable cost (e.g., geometric designs not based on right angles), above all when the work has to be done on-site and the items to be connected are ducts.

Traditional methods for building these types of structures with ducts include soldering and bolted flange joints. Although these techniques are simple and available at any metal workshop, they are particularly expensive when the structures are large and the connections must be done on-site. For example, soldering ducts outside of a workshop is difficult and making flanges requires a lot of soldering and modifications to duct ends. In addition, there are architectural solutions for building trusses with ducts, but their nodes are often solid and rod ends also require modification. This negatively impacts its mechanical properties, meaning that more materials are consumed and costs increase.

The business Anisopter Insightful Research S.L. was founded in 2021 to remove these limitations with an ingenious connection system invented by the founding partner. This system uses light and hollow nodes specifically designed to cost-effectively connect ducts on-site with bolts and without soldering.

2. So, what exactly do you do? What is your business model?

Anisopter is a start-up dedicated to researching, developing, and marketing connection technologies for the optimisation and efficient building of trusses. We invest most of our resources in R+D+i together with industrial, technological, and academic partners. Due to the large number of industrial sectors that may benefit from our solutions, the business model is continuously evolving. However, it is structured around three fundamental pillars:

- The patented connection system for efficiently connecting ducts on-site and without soldering.

- Development and application of tailored structural optimisation methodologies that highlight our construction solutions.

- Planning and execution of R+D+i projects (public or private) with the aim of adapting and validating our technologies for any industrial sector.

3. What are Anisogrid lattice structures and what are they used for?

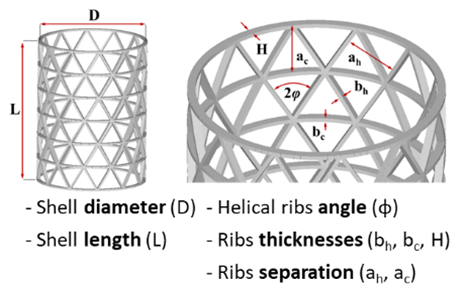

The grid or lattice structures consist of triangulated meshes made of solid carbon fibre rods, usually cylindrical or truncated conical single-layer shapes. They are used in the aerospace industry when companies seek maximum performance in terms of rigidity and lightness, as is often the case in satellites and space shuttles.

The word Anisogrid simply refers to the fact that the dimensions of the rods as well as the angles between them may be unequal (anisos, “unequal”). And it is precisely this which makes it possible to find the best configurations to withstand loads and reduce weight to a minimum, despite the design complications associated with optimising a greater number of variables.

The use of ducts in this type of triangulated truss is the main structural concept that inspires our designs. The triangulation of the rods provides rigidity, the high number of variables leaves room for optimisation and the use of rods contributes to reducing material consumption to a minimum.

4. Why a dragonfly?

Dragonflies inspired the name and logo of Anisopter as Anisoptera means dragonfly in Greek (anisos, “unequal” - pteron, “wing”). Both the unequal wing structure, which provides them with greater manoeuvrability and efficiency in flight, and their advanced vision makes them excellent predators, with one of the greatest success rates in nature (over 95%). In a sense, their success inspires and encourages us to makes our customers happy at least 95% of the time.

5. Thanks to our joint collaboration in the ANISOPTER project, we have been able to begin studying the validity of your proposals in terms of efficient structural designs taking the needs of our pylons as a starting point. What can Anisogrid structures and your nodes provide in this field of application?

As previously stated in the first part of the ANISOPTER Viability Study, high-voltage pylon requirements are very different from those of aerospace structures. For example, they must be easy to install, able to withstand extreme environmental conditions (e.g., winds of 140 km/h), designed with a useful life of at least 40 years, minimising maintenance tasks and with no increase in investment costs compared with traditional solutions, as electricity transmission is a regulated activity.

In order to meet these demands, we propose a new truss tower design inspired by Anisogrid aerospace concepts but made with steel rods and adapted to our market. The use of rods and their thoroughly optimised design would not only result in reduced material consumption, but would also help to mitigate the visual impact of the lines and control costs.

Unlike traditional truss towers, their aesthetic is more pleasant and balanced as the angles between the rods vary slightly with the height to convey peace and harmony. In addition, the greater stability of the rods compared to angular profiles means that a reduced number of components (rods and connections) are used, which means the structures are better integrated with the countryside. This reduced number of components may also speed up assembly and contribute to cost decrease/maintenance.

Unfortunately, building these structures with traditional methods (soldering or flange joints) is more costly because, as previously mentioned, soldering rods on-site is difficult and making flanges requires a large amount of soldering in workshops. On the contrary, we believe that the simplicity of our nodes and their ingenious assembly system will soon be an effective alternative to promote this type of structure.

It is precisely to overcome these disadvantages that we have just started the second phase of the Anisopter viability study, which consists of adapting and validating our connection system to the most demanding sector requirements. After due development, and thanks to help from Red Eléctrica and Elewit, we hope that over the next few years, installing the new pylons will be commercially viable and at a reasonable cost. Once the new system has been validated and the viability study has been completed, the application of this technology will be analysed in pilot projects to assess their performance in real working conditions.

In summary, our pioneering contribution to meet the demanding requirements of high-voltage pylons is based on three key innovations:

- An optimised design that is more visually pleasing, inspired by Anisogrid structures.

- Use of the greater mechanical properties of the rods.

- Use of effective nodes to connect said rods on-site in a cost-effective way.

Integration of these three innovations in the design will create a synergistic effect that will be key to the project’s success.

6. How does your solution contribute to the energy transition?

The changes in production, transmission and energy consumption models that promote the energy transition, are aimed at sustainable electrification of the energy system through renewable energy sources. The incorporation of the electric vehicle, heat pump air conditioning and self-consumption are clear examples.

In order to address these increases in electricity demand, it is essential to build new overhead lines. Only this method will enable us to integrate all new renewable capacity (sun and wind) and create the necessary interconnections to ensure the system’s stability and guarantee supply.

However, there is a very long processing and execution time for projects (5-10 years), which can be even longer due to the low social acceptance which overhead lines often experience.

Whereas our pylons are intended to reduce the social impact caused by electricity infrastructure. According to our forecasts and after due to development, the new Anisopter pylons could help reduce steel consumption, installation time, and the visual impact of overhead electricity transmission lines. These benefits may guarantee execution times while controlling costs, particularly on the most challenging issues.

The Anisopter project represents Redeia’s interest and commitment to be at the cutting-edge of technology and to promote sustainability and competitiveness of its core business.

7. How would you evaluate your experience working with Elewit?

Elewit is an essential technology accelerator that not only serves as a link between Redeia lines of business and external companies with innovative ideas, but also actively participates in conceptualisation and design of business cases to maximise the impact of the proposals.

Relying on the team of experts from the start has been a great help because it has helped us enormously when it comes to presenting and adapting our proposals to the most appropriate lines of business. Without their initial involvement in the project, it would have been very difficult to access suitable interlocutors to get it started. They are also responsible for good project management and are concerned with the purely business aspects throughout the collaboration. They are an essential partner for innovation at Redeia.

We would also like to take this opportunity to thank the Spanish CIGRE (International Council on Large Electric Systems) Secretariat for their support and for having put us in contact with Elewit, the Line Engineering Department at Red Eléctrica for its involvement in the project, and the entire Elewit team for the warm welcome to ANISOPTER.

8. Looking to the future, how do you see yourselves in 2030?

Although we still don’t have a crystal ball, we’re very optimistic. At Anisopter, we firmly believe that the benefits of our system will be the key to optimising building technologies and contributing to social development. The new methodologies using connection nodes could reduce costs until they are more viable, making projects that structural engineers could only previously imagine possible.

To make this ambitious future a reality, we are currently adapting and optimising our connection system for different industrial sectors with a high social and environment impact with the aim of checking the performance of the proposed solutions and comparing them with traditional alternatives. The preliminary results are very promising.

However, we are aware of the magnitude of the challenge at hand and it will soon be necessary to incorporate different actors with experience in the sector into the project, to actively participate in the development and marketing of the new pylons. With their help, we hope that it will soon be possible to include the Anisopter family of pylons as a solution to consider for the design of new high-voltage lines.

In addition to this project for the electricity transmission sector, we are also promoting similar initiatives for the generation of renewable energies and to facilitate access to space. In particular, we hope that our solutions will soon be able to be used to reduce costs in the construction of wind turbine towers, solar chimneys, and even satellite structures or space launch systems.

José Ramón López-Blanco

Scientist and Managing Director of Anisopter